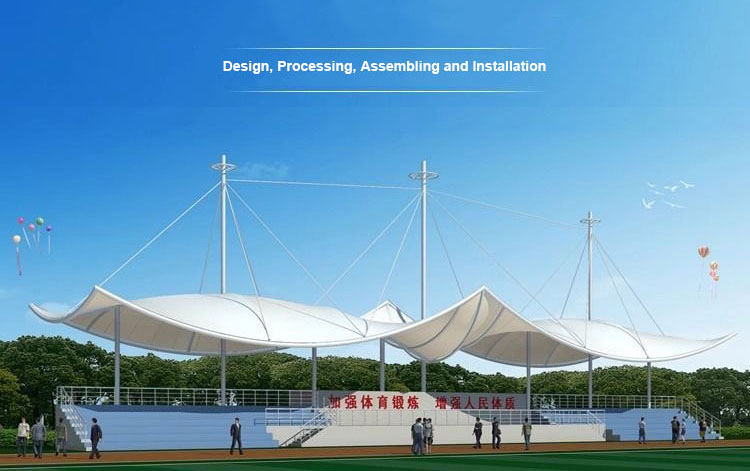

Residential Carport for Villa

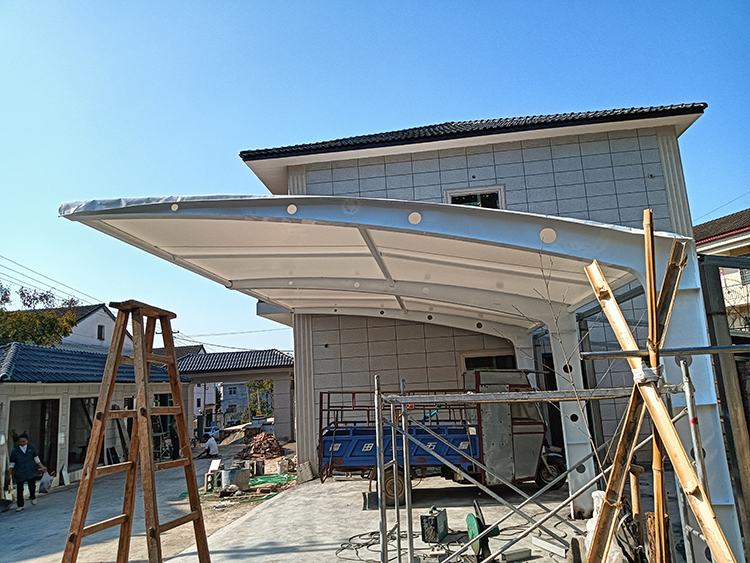

A Structure Shade for Villa Car Parking is a custom-designed, architecturally elegant shelter that protects vehicles from sun, rain, and debris while enhancing the villa’s aesthetic appeal. Unlike standard carports, these structures combine engineering precision with luxury design, making them ideal for high-end residential properties.

A membrane structure shade is the perfect solution for villa car parking due to its unique combination of aesthetics, functionality, and durability.

Why Choose a Membrane Structure Shade for Your Villa?

✅ Aesthetic Appeal – Complements luxury villa architecture.

✅ All-Weather Protection – Shields cars from sun, rain, and dust.

✅ Space Efficiency – No obstructive columns, maximizing parking space.

✅ Durability – Resistant to rust, corrosion, and UV damage.

✅ Customizable – Choose colors, shapes, and sizes to match villa style.

Installation & Maintenance for Membrane Structure Shade for Your Villa

Fast Setup: Prefabricated parts allow quick installation.

Low Maintenance: Occasional cleaning (no repainting needed).

Optional Add-Ons: LED lighting, solar panels, or automated drainage.

Membrane Structure Shade for Your Villa is Perfect for Luxury Villas!

Whether you prefer a floating tensile design or a sleek cantilever shade, a well-designed structure shade enhances both functionality and elegance for your villa’s car parking needs.

Need a custom design? Let’s create your dream car shade!

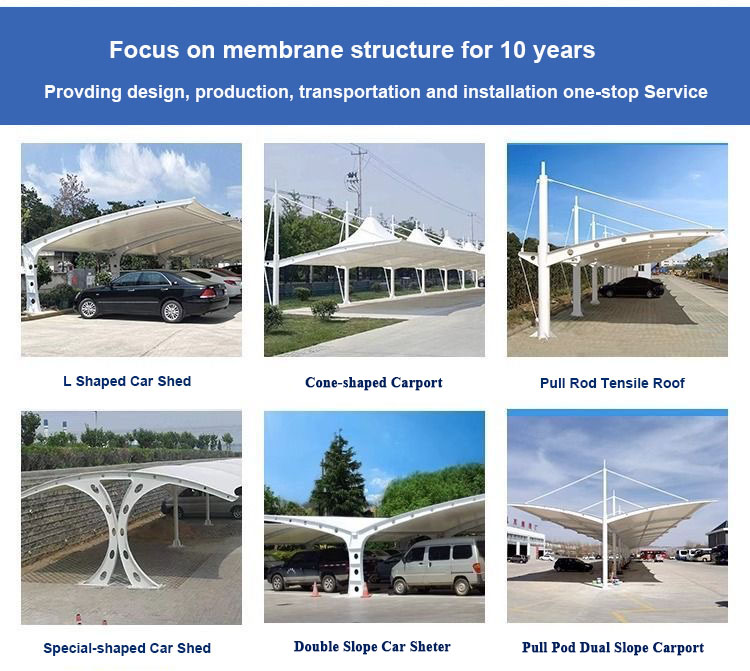

We professionally manufacture and supply one-Sided and double sided pull rod cantilever Parking Shades, offering a variety of size options that can be customized to your specific requirements.

[ Our Standard Sizes Are]

Available standard specifications include:

✓ 6.0m × 3.0m (suitable for 1 car)

✓ 6.0m × 6.0m (accommodates 2 cars)

✓ Standard clearance height: 2.5m (height customizable)

Note: All dimensions can be adjusted as needed.

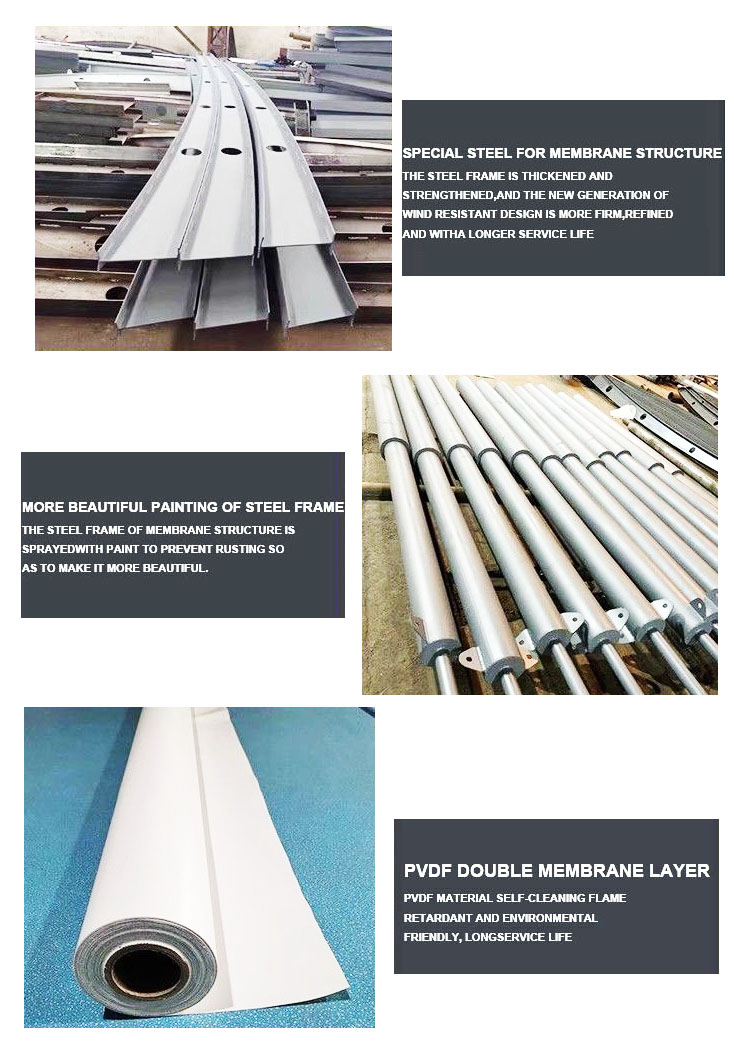

[Shades Materials]

Optional materials:

✓ PVC waterproof fabric

✓ PTFE membrane

✓ High-density polyethylene (HDPE)

✓ Fiberglass reinforced plastic (FRP/GRP) panels

[Support Structure]

Structural configuration options:

✓ Base plate fixation

✓ Recessed base plate

✓ Embedded mounting design

(Note: This product supports full-size customization, and all structural components undergo anti-corrosion treatment for long-lasting durability.)

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: kelly Wong

Phone: +86-19911319693

E-mail: support@aolii.com

Add: Office Address: Building 10, Hejiaping Creative Industrial Park, Wuling District, Changde City, Hunan Province, SASTON

Factory Address: Building 003, Industrial Park, Wuxi Town, Luxi County, Tujia and MiaoAutonomous Prefecture,Xiangxi. Hunan Province