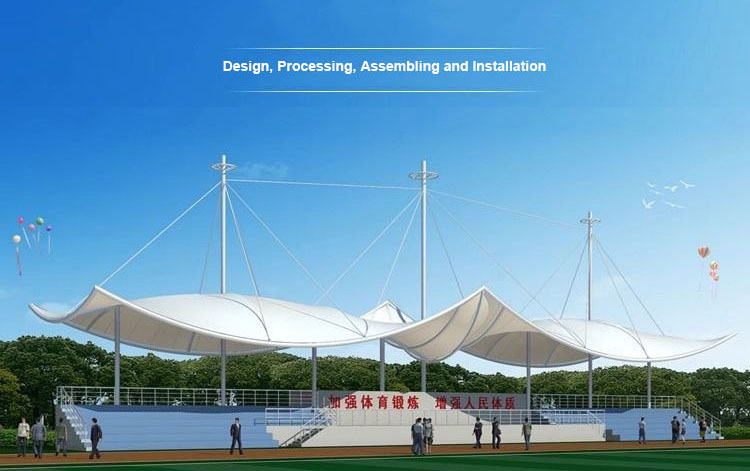

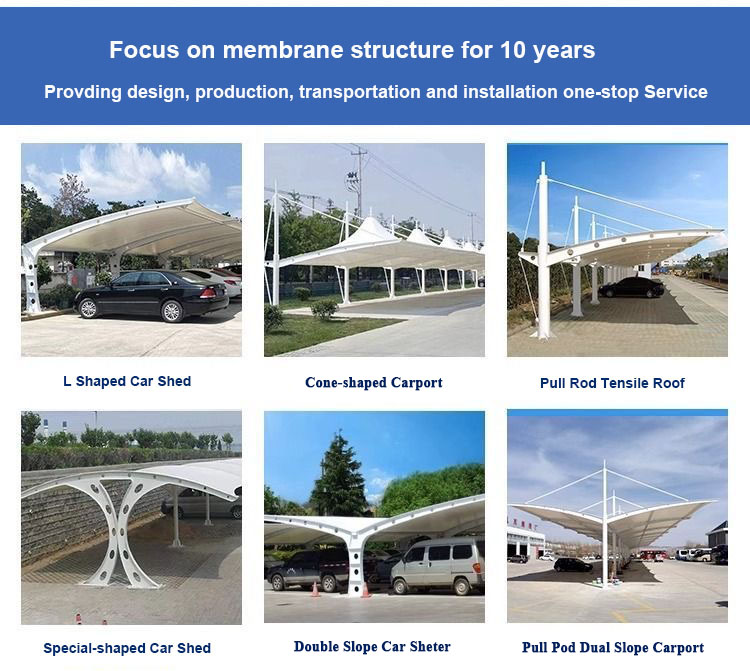

Tensile Membrane Cantilever Car Parking Shades

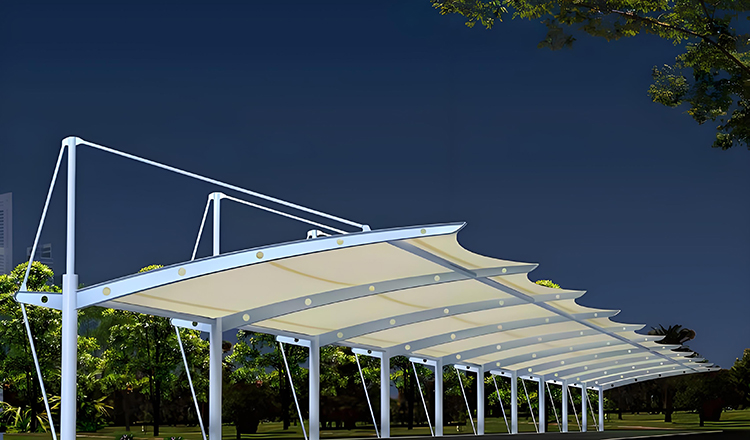

A Pull Rod Tensile Membrane Cantilever Car Parking Shade is a modern, lightweight, and durable structure designed to provide shade and protection for vehicles using a tensioned membrane system supported by a cantilevered framework with pull rods for stability.

Here is a reakdown of its features:

1. Tensile Membrane Structure

Made from high-strength, flexible fabric (like PVC-coated polyester or PTFE-coated fiberglass) stretched tightly over a steel frame.

The membrane is engineered to withstand weather conditions (UV rays, rain, wind) while remaining lightweight.

2. Cantilever Design

The shade is supported by cantilever beams (horizontal extensions anchored at one end), allowing for column-free space underneath, maximizing parking area usability.

Ideal for locations where ground obstructions (like pillars) need to be minimized.

3. Pull Rod System

Pull rods (or tension rods) are used to reinforce the structure, ensuring stability against wind uplift and dynamic loads.

They help maintain the pre-tension of the membrane, preventing sagging and improving durability.

Advantages of Tensile Car Parking Shades

✔ Aesthetic & Modern Look – Sleek, curved designs enhance visual appeal.

✔ Durability – Resistant to corrosion, rust, and extreme weather.

✔ Cost-Effective – Requires fewer materials compared to traditional roofing.

✔ Easy Installation & Maintenance – Lightweight and modular assembly.

The Comparison Between Tensile Cantilever and Traditional Car Shades

| Feature | Pull Rod Tensile Cantilever | Traditional Metal Shade |

|---|---|---|

| Support | Cantilever + Tension Rods | Columns & Beams |

| Material | Lightweight Membrane | Heavy Steel/Aluminum |

| Aesthetics | Modern, Curved Designs | Conventional Flat Roof |

| Wind Resistance | High (Pre-tensioned) | Moderate |

Why Choose This System?

✅ 2X More Parking – One structure covers twice the vehicles

✅ Architectural Statement – Sleek, modern appearance

✅ Low Lifetime Cost – Minimal maintenance vs. metal carports

Example: A luxury mall installed 12 double-sided units, covering 48 cars while saving 40% ground space vs. traditional shelters.

Need CAD drawings or wind load analysis? Contact our engineers!

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: kelly Wong

Phone: +86-19911319693

E-mail: support@aolii.com

Add: Office Address: Building 10, Hejiaping Creative Industrial Park, Wuling District, Changde City, Hunan Province, SASTON

Factory Address: Building 003, Industrial Park, Wuxi Town, Luxi County, Tujia and MiaoAutonomous Prefecture,Xiangxi. Hunan Province